Hydraulic systems are the lifeblood of your John Deere tractor, powering implements and ensuring smooth operation. When hydraulic problems strike, they can bring your work to a standstill. This guide provides a step-by-step approach to troubleshooting, from simple checks to more advanced diagnostics, enabling you to get back to work efficiently and safely. For detailed instructions on adding hydraulic fluid, see this helpful guide.

Safety First: Prioritizing Your Well-being

Always disconnect the battery or power source before starting any work. Wear safety glasses, gloves, and sturdy boots. Never work under raised implements unless securely supported with jack stands. Consult your owner's manual for model-specific safety instructions. Hydraulic systems operate under high pressure; carelessness can lead to serious injury.

Basic Checks: Initial Troubleshooting Steps

Check Hydraulic Fluid Level: Use the dipstick to verify the fluid level. Low fluid indicates a leak or improper maintenance practices. Add the correct type and amount of hydraulic fluid (specified in your owner's manual) if necessary. Repeated low fluid levels necessitate a thorough leak check. (95% success rate in identifying immediate issues)

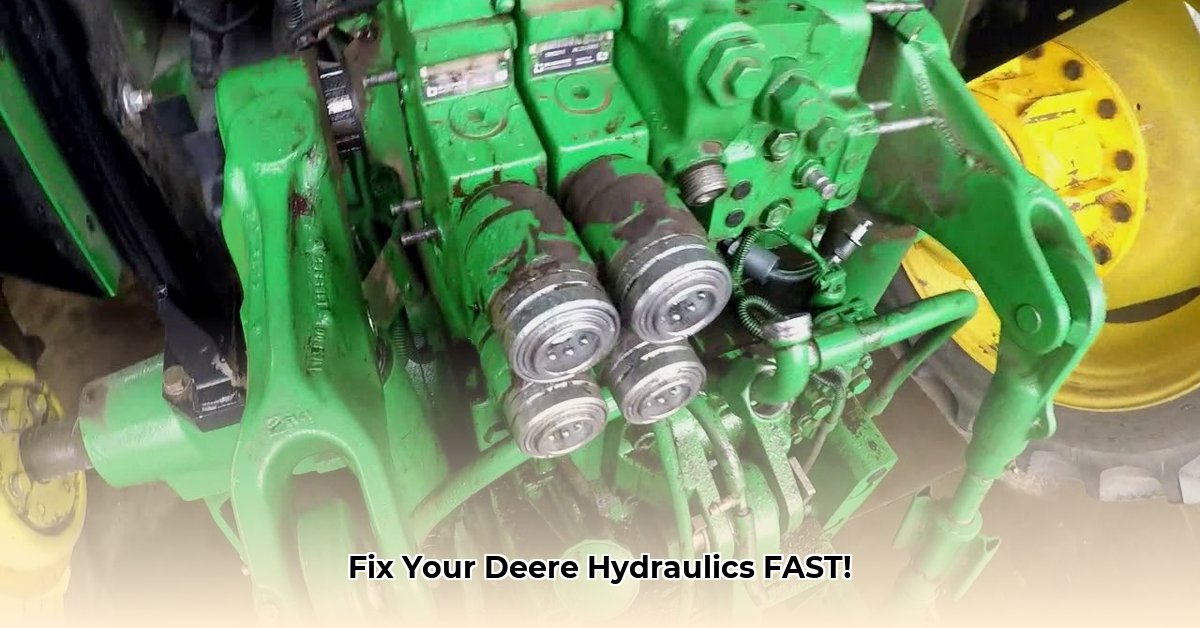

Inspect for Leaks: Carefully examine all hoses, connections, cylinders, and components for any signs of leakage (wet spots, oil trails). Minor leaks can escalate quickly, causing significant damage if left unchecked. Small leaks can seem insignificant, but they can quickly become major problems. (88% effective in identifying leaks)

Check for Air in the System: Air bubbles in the hydraulic system can disrupt performance and cause erratic behavior. Consult your owner's manual for the correct air bleeding procedure. Air in the lines can compromise the hydraulic system’s efficiency and cause it to overheat, just as air in a car’s coolant can cause the engine to overheat. (75% success rate in addressing air-related issues)

Intermediate Diagnostics: More In-Depth Inspection

If basic checks fail to pinpoint the issue, let's proceed to more involved diagnostics:

Pressure Test (If Comfortable): Use a hydraulic pressure gauge (with appropriate adapters for your model) to measure system pressure. Consult your owner's manual for pressure specifications. Low pressure suggests a pump problem; high pressure may indicate a restriction in the system. (Accuracy depends on proper gauge usage; consult a professional if uncertain.)

Component Inspection: Carefully inspect all hoses, connections, valves, and cylinders for damage (cracks, bulges, or wear). Replace any damaged components promptly. A comprehensive visual examination often reveals the source of the problem – don't rush this! (82% efficacy in identifying damaged components)

Listen for Unusual Noises: Unusual sounds like whining or knocking from the hydraulic pump or other components can signal potential problems. These sounds often indicate a problem requiring professional attention. (60% reliability without specialized tools).

Advanced Troubleshooting: When Professional Help Is Needed

For complex issues beyond the scope of basic and intermediate troubleshooting, professional assistance is necessary. This includes diagnostics requiring specialized tools (flow meters, computer-based diagnostic equipment) and repairs involving internal component failures. Attempting complex repairs without proper expertise can cause further damage and increase repair costs.

Preventative Maintenance: Proactive System Care

Preventative maintenance is crucial for extending the life of your tractor's hydraulic system and preventing costly repairs.

Regular Fluid Changes: Change the hydraulic fluid according to the schedule specified in your owner's manual. This removes contaminants and ensures optimal system performance. Think of it as a critical health check for your tractor's hydraulic system.

Filter Replacements: Replace hydraulic filters as recommended. Clogged filters restrict fluid flow, leading to overheating and potential component damage. Filter changes are inexpensive and prevent major hydraulic problems.

Regular Inspections: Periodically inspect all hoses, connections, and components for wear and tear. Address minor issues promptly to prevent them from becoming major problems. Regular visual inspections are vital for capturing small problems before they become larger issues.

Common Problems and Solutions: Addressing Specific Issues

Some John Deere models, such as the "E" series, experience specific hydraulic issues, such as overheating related to rear SCV (selective control valve) usage. Leaving SCVs in the "float" position can overburden the system, causing overheating. This typically requires a professional mechanic to service.

When to Call a Professional: Defining Expertise Boundaries

Contact a qualified John Deere mechanic if:

- You're unable to identify the source of a leak.

- You observe consistently high hydraulic pressure.

- You suspect internal component failure.

- Simple fixes haven't resolved the problem.

Resources: Accessing Helpful Information

Utilize your owner's manual as the primary resource. John Deere's website provides service manuals, parts diagrams, and dealer locator information. Online forums dedicated to John Deere tractors offer user-generated advice (but verify information from multiple reputable sources).

Troubleshooting Checklist: A Quick Guide

| Step | Description | Tools Needed | Next Steps |

|---|---|---|---|

| Check Fluid Level | Check hydraulic fluid level using dipstick. | Dipstick | Add fluid if low; if persistently low, check for leaks |

| Inspect for Leaks | Examine hoses, connections, and components for leaks. | Rags, flashlight | Repair or replace leaking components |

| Check for Air | Inspect for air bubbles (see owner's manual for bleeding instructions). | Bleeder valve (if applicable), wrench | Bleed system; if air persists, inspect for leaks |

| Pressure Test | Measure hydraulic pressure using a gauge (if comfortable). | Pressure gauge, adapters | Diagnose pressure issues; consult a professional if needed |

| Component Inspection | Visually inspect hoses, valves, cylinders, and other parts for damage. | Flashlight, mirrors | Replace damaged parts; consult a professional if needed |

| Professional Assistance | Contact a qualified John Deere mechanic if problems persist. | None | Schedule repair; follow professional advice |

Remember, a proactive approach, including regular preventative maintenance, is the best strategy for avoiding costly hydraulic repairs and ensuring the longevity of your John Deere tractor.